Archives

Business, Feature, Freight News, Logistics, Sea

Could the Stockport twins revolutionise container shipping?

[ February 23, 2013 // Chris ]Stockport-based Container Group Technology (CGT) says it has revolutionised container design that can offer 36% more pallet space.

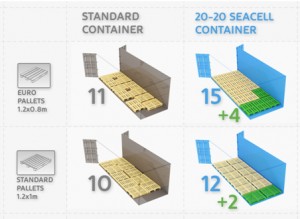

The 20-20 SeaCell Container can pack in 15 Euro-pallets (1200mm x 800mm) instead of just 11 Euro-pallets in a standard ISO 20ft dry container. It achieves this, says CGT, because it is exactly 20ft long externally and 2426mm wide internally, whereas standard 20ft containers are, in fact, only 19ft 10½ ins (6058mm) long externally and 2330mm wide internally. This extra 1 1/2” internal length, a flat front panel and thinner doors increase the internal dimensions enough to squeeze the extra pallets in.

The door opening width is 2408mm which allows fork-lift trucks to load pallets two or three at a time and, by using 100% of the floor area, pallets fit snugly together inside the container making the 20-20 ideal for lightweight slip-sheets or paper pallets, reducing costs and increasing useable volume and payload.

Moreover, two 20-20 containers can be locked together from the outside with no special tools using an integral locking mechanism in the corner casting to make a 40ft box and two 20-20 containers will carry six more pallets than one standard 40ft. an integral locking mechanism in the corner casting is activated from the outside the container.

It is also possible to mix Euro & Standard pallets in the same 20-20 and still have 100% pallet utilisation, says CGT.

The 20-20 is fitted with larger corner castings of the type typically used in flatrack containers, enabling them to be lifted by standard 20ft or 40ft spreaders, loaded singly or as a pair into a container ship’s 40ft cells or onto any current road chassis and rail wagon.

In just a few minutes, the two 20-20 containers can be securely locked together and lifted as a single ‘40ft’ unit. In the standard configuration, two 20-20s are joined at the front ends, ie, with the doors accessible at each end of the combined containers. However,

If requested CGT can also position the locking mechanism at the door-end corner castings so that the two 20-20 units are effectively sealed until reaching their final destination for high value or sensitive cargoes.

If the containers are heavily laden, they can be separated and lifted individually, but if they are empty, or lightly loaded they can be locked together and lifted as a 40′ – potentially saving on stevedoring costs. FBJ understands that two shipping lines are considering using them on the Asia/US trades in this way.

Prototypes have been built and fully tested in China, and the new design is available for sale or lease.

Tags: 20-20 SeaCell Container, Container Group Technology